Thin film coatings for ultra-high vacuums

CERN experts have significant expertise across a range of thin film coating techniques for producing High & Ultra-High Vacuum, particularly Non-Evaporable Getter (NEG) thin film coatings. NEG coatings are produced by sputtering an alloy of several selected metals onto a vacuum chamber wall. When activated by heating, the NEG chemically reacts to reduce the amount of gas in the vacuum chamber. NEG coatings also block the outgassing of the underlying vacuum chamber walls.

In quantum computing, achieving and maintaining a reliable vacuum is crucial to isolate qubits from their environment, and doing so with small and lightweight system will play an important role in achieving scalability. The use of NEG coatings enables passive pumping, removing the need for bulky ion pumps. CERN’s NEG coatings are able to achieve a lower vacuum with a lower activation temperature than other solutions, making them an ideal candidate for quantum systems.

CERN experts can provide consultancy and training for the application of NEG coatings.

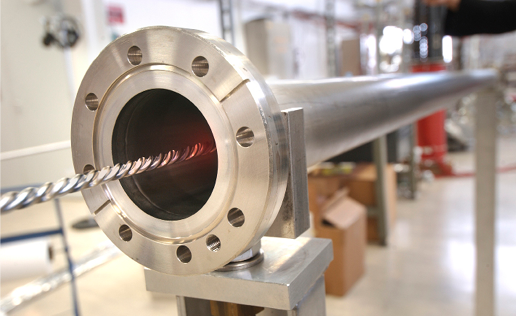

Thin film coatings for superconducting RF cavities

CERN possesses world-leading expertise in the design and manufacturing of high quality factor RF cavity resonators, following decades of their use to accelerate particles. Different applications require different geometries and materials to achieve optimal performance. In addition to RF cavities manufactured using bulk materials, CERN has demonstrated outstanding performance of copper RF cavities internally coated with a superconducting niobium thin film.

This high performance of these niobium-copper cavities is prominent at low temperatures and electric field strengths, which directly reflects the conditions required for circuit quantum electrodynamics (CQED). CQED is a quantum computing architecture in which photons are used to transfer information to, from and between superconducting qubits. Photons are trapped within resonator cavities, and achieving a long photon lifetime is crucial to achieve scalable systems.

CERN is looking for opportunities to collaborate with companies to apply its expertise in niobium-coated RF cavities to quantum computing.

Advantages & Applications

Applications

- Quantum computing

- Cold atom systems

- Improvement of pumps or creation of innovative pumps

- Electron and cathode tubes

- Vacuum thermal insulation at high temperature (solar applications)

- Vacuum components of any types (blanks, bellows, crosses, Tees, transitions) to replace or complement pumps of other types

- Microelectronics

- Vacuum thermal insulation at low temperature

Specifications

Specifications

- NEG coatings: Baking at temperature in the range 180°C to 400°C

- NEG coatings: Ultra-high vacuum is achieved (10e-13 Torr)

Advantages

- NEG coatings: Reversible process for hydrogen

- NEG coatings: Up to 50 venting cycles possible with marginal performance loss

- NEG coatings: The chemical reactivity of the NEG can be recovered by heating at temperature as low as 180°C

- Superconducting niobium coatings: High quality factor at low temperatures and electric fields

- Superconducting niobium coatings : Tight control of field amplitude and phase

Limitations

- NEG coatings: Cannot be exposed too often to ambient air

- NEG coatings: Requires high degree of know-how

- Superconducting niobium coatings: Requires high degree of know-how