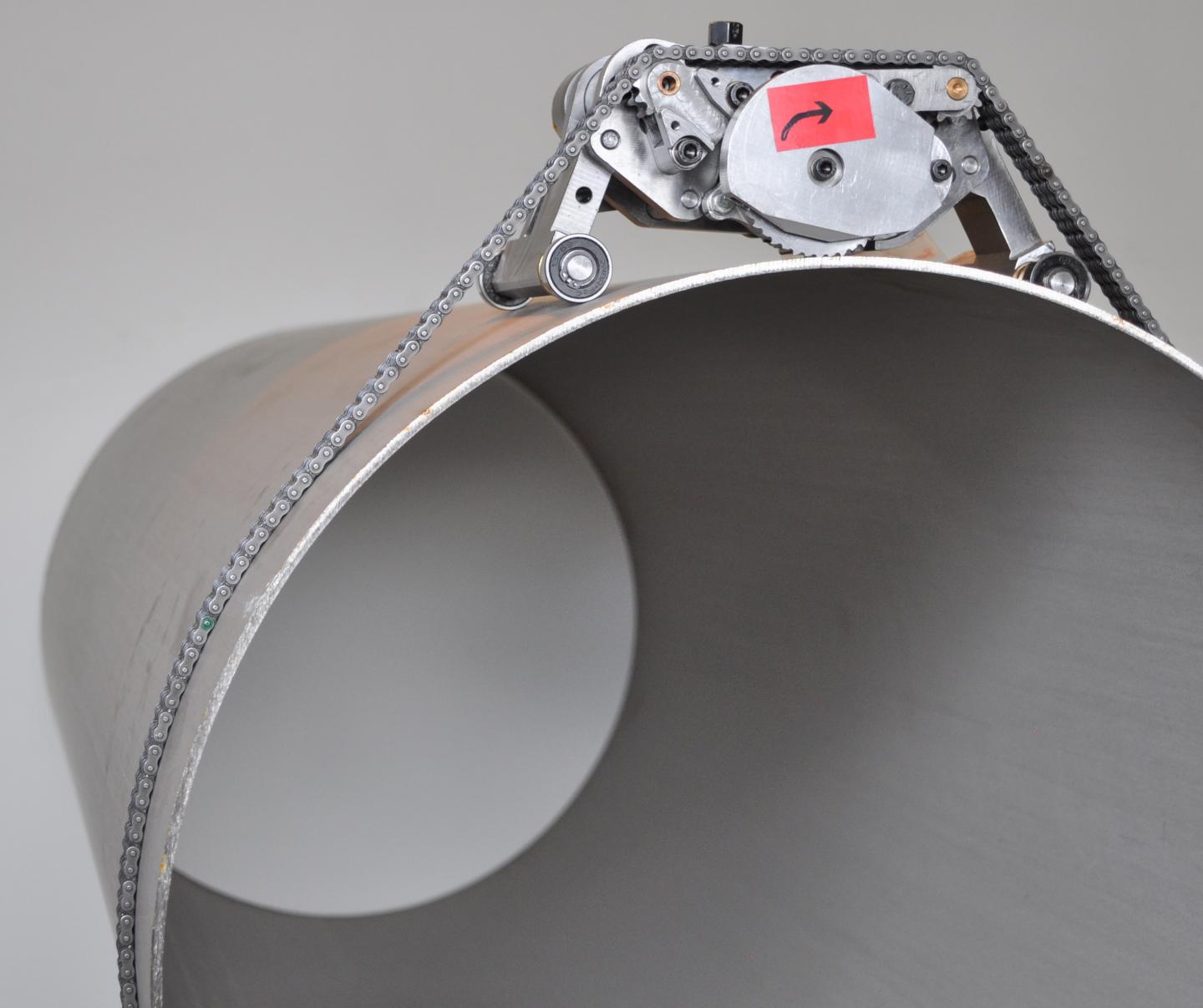

CERN developed the orbital cutting machine for repair of awkwardly located pipes in tight spaces. It is relevant for the industrial piping needs of accelerator facilities, as well as in sectors with environmental hazards, such as oil and gas piping, heat exchangers, and piping in nuclear plants.

Advantages & Applications

Advantages

- Solution more compact with respect to other solutions on the market

- Easily adaptable to a wide range of pipe diameters, thickness and material

Applications

-

High energy physics laboratories.

-

Nuclear facilities.

-

Oil and gas industry.

Specifications

Specifications for machine development

- The device includes: a chain which holds the machine in contact with the tube and allows the machine to move around the tube; a power supply and control for electric motor (for machine displacement); a hydraulic power supply (for autonomous cutting)

- Cuts pipes in a range from 100 mm in diameter to 1200 mm in diameter (maximum pipe thickness 7 mm)

- Hydraulic motor power - 1100 W

- Electric motor power - 15W

- Blade idle speed - 80 to 300 rpm

- Blade diameter – 68mm

- Cutting speed - 20 – 60 mm/min

- Feeding system - Steel wheels

- Machine rotation direction - Clockwise or Counter-Clockwise

- Feeding speed - Manual

- Weight (body only) – 5kg

- Pipe locking system - Chain

- Guiding system - Chain

Status

Event

1st prototype manufactured at CERN, 2nd prototype manufactured at G.B.C. Industrial Tools S.p.A.

Licensing

Know-how (detailed designs and schematics)